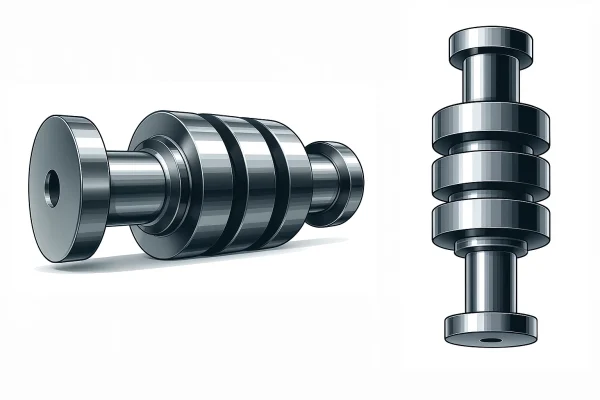

What is a Stiffer Cam Shaft?

The Stiffer Cam Shaft is a crucial mechanical component used in railway engine and system assemblies to control the timing and operation of valves or other moving parts. Its stiffer design enhances rigidity and precision, enabling the camshaft to perform optimally under heavy-duty operational stresses specific to railway applications.

Key Features of Stiffer Cam Shaft

High Rigidity

Designed with increased stiffness to resist bending and torsional stresses, ensuring consistent valve timing accuracy.

Precision Machining

Manufactured with tight dimensional tolerances to maintain smooth engagement with valve lifters or actuators.

Durable Material

Made from high-grade steels or alloys treated for enhanced wear resistance and fatigue strength in harsh railway environments.

Optimized Cam Profiles

Engineered cam lobes provide precise control over valve opening and closing sequences for efficient engine operation.

Compatibility

Suitable for integration with various railway diesel and electric locomotive engines, supporting diverse operational requirements.

Valve Timing Control: Enables accurate control of intake and exhaust valve opening and closing, critical for engine performance.

Converts Rotational to Reciprocating Motion: Transforms the camshaft’s rotational movement into linear motion to operate valves or other mechanical systems.

Maintains Engine Efficiency: Ensures optimal air-fuel mixture intake and exhaust gas expulsion to maximize combustion efficiency.

Withstands Heavy Loads: Performs reliably under high mechanical loads and vibration typical in railway engine operation.

Supports Automated Engine Operation: Coordinates with electronic or mechanical controls to adapt to varying engine speeds and loads.

Reduces Wear on Valve Components: Stiffer design minimizes deflection, preventing premature wear and ensuring longer service life.

Enhances Overall Engine Reliability: Provides consistent and repeatable valve actuation, critical for continuous, fault-free train operation.