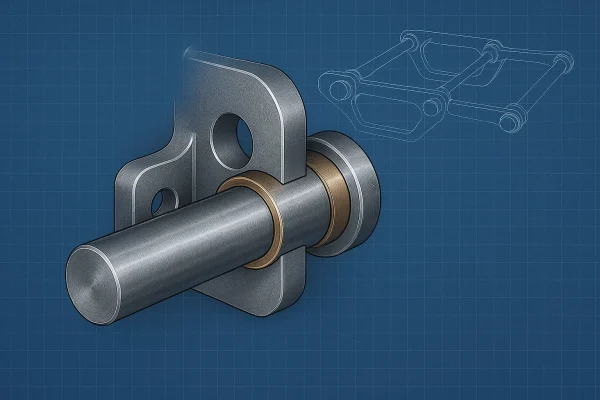

What is a Pin and Bushes?

Pins and bushes are fundamental mechanical components used extensively in railway bogie assemblies and brake rigging systems. They serve as pivot and connection points, facilitating relative motion between different parts while bearing heavy loads and ensuring structural stability.

Key Features of Pins and Bushes

High Strength Material

Manufactured from hardened alloy steel (such as grade 817M40/EN24) providing excellent load-bearing capacity and resistance to wear.

Precision Manufacturing

Made to tight dimensional tolerances for accurate fitment and alignment in assemblies.

Corrosion Resistance

Often surface-treated or coated to resist oxidation and degradation due to exposure in varied environmental conditions.

Wear-Resistant Design

Engineered to sustain repeated mechanical motion and reduce friction between moving parts.

Interchangeable Parts

Designed for interchangeability within railway standards to simplify repairs and replacements.

Enabling Pivot Motion: Pins act as pivot points allowing controlled rotation or articulation within bogie suspension and brake linkages.

Load Transmission: Transfer mechanical forces between connected components reliably under dynamic railway conditions.

Reducing Wear on Components: Bushes serve as wear surfaces, protecting expensive structural parts from direct frictional damage.

Maintaining Alignment: Ensure proper alignment of connected parts, preventing misfit and mechanical failures.

Facilitating Smooth Movement: Provide low-friction bearing surfaces to absorb shocks and reduce noise.

Simplifying Maintenance: Easily replaceable pin and bush sets reduce downtime and speed up corrective maintenance.

Increasing Durability of Assemblies: Extend the lifespan of bogie and brake system assemblies by absorbing and distributing mechanical stresses.