Defence Components

Precision for Mission Critical Systems

Engineered for Excellence

Built for Protection

In the demanding world of defence, failure is not an option. Our components are manufactured using advanced materials and stringent quality control, ensuring high tolerance, durability, and flawless performance under extreme conditions. We are a trusted partner in providing mission-critical parts for national defence programs.

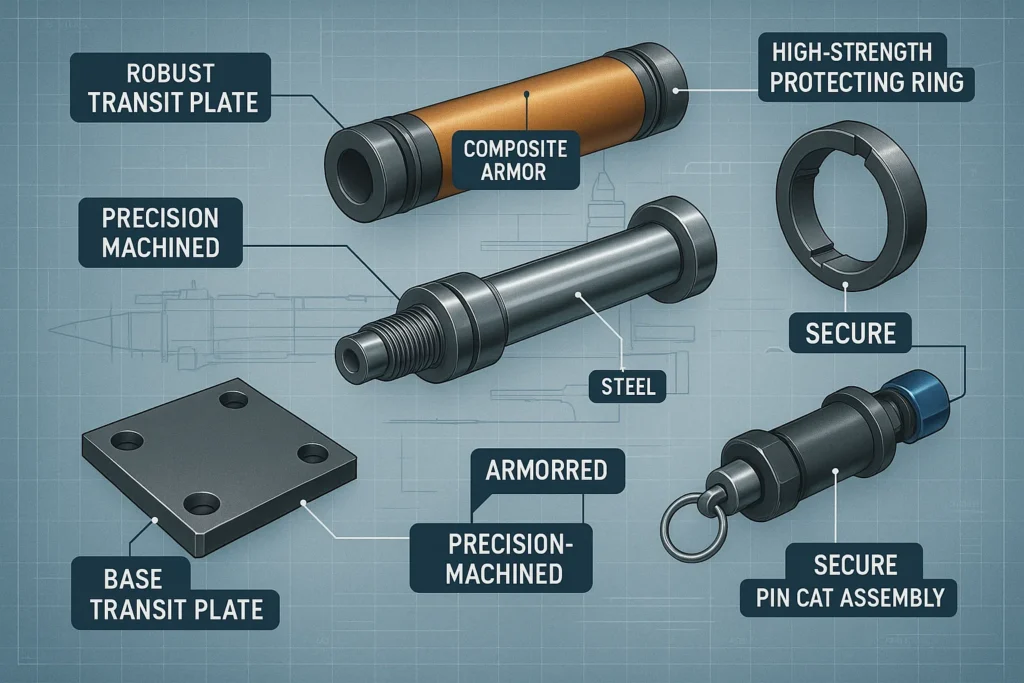

Key Components Highlight ━

- Base Transit

- Core Barrel

- Charge Carrier

- Protecting Ring

- Pin Cat

Components Description

We present a detailed breakdown of the system’s parts, outlining their individual functions and purposes.

Base Transit

Base Transit encompasses the essential operations and infrastructure dedicated to the efficient and secure movement of personnel, materiel, and vehicles across and between military installations.

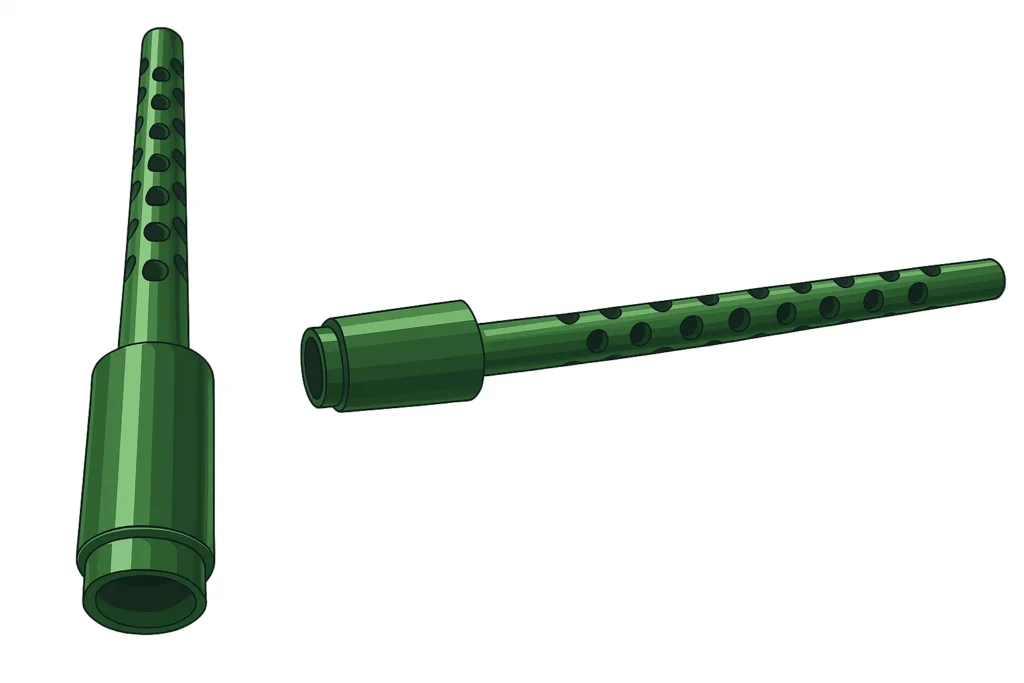

Core Barrel

Core Barrel component primarily refers to the essential geotechnical and engineering capabilities required for critical infrastructure development and security.

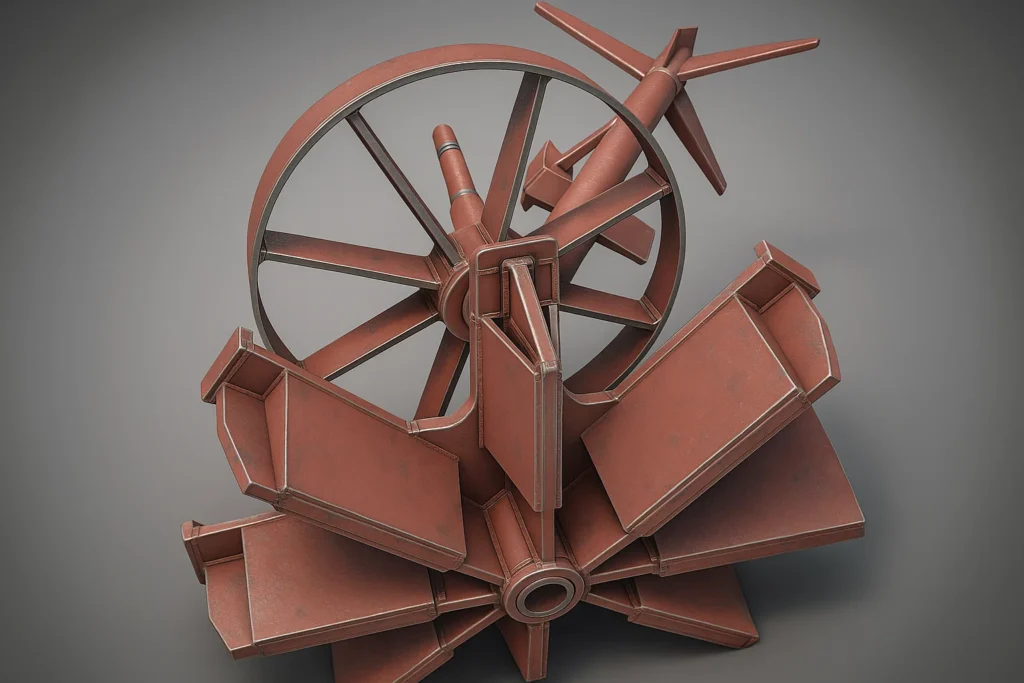

Charge Carrier

The Charge Carrier component signifies the critical underlying technology that powers the sophisticated electronic systems found in modern defense platforms, such as the advanced fighter jet pictured.

Protecting Ring

The Protecting Ring component emphasizes the critical engineering dedicated to safeguarding sensitive and high-value defense technologies, as exemplified by the robust design protecting the intricate sensor system pictured.

Pin Cat

A Pin Cat is a specialized locking pin used in defence and heavy engineering applications, designed for securely fastening, aligning, or locking mechanical components subject to high loads. These pins are manufactured from hardened, corrosion-resistant steel for maximum strength and wear resistance.

Choosing the right partner for defence manufacturing is critical. Our commitment goes beyond components — we offer a strategic partnership built on proven capability, stringent quality control, and absolute confidentiality.

- Zero-Defect Philosophy

- Traceability and Reliability

- Specialized Alloys

- Maximum Resilience

- Collaborative R&D

- Scalable Manufacturing

- Strict Security Protocols

- Controlled Access

Commitment to Quality: The organization prioritizes delivering high-performance products and services, supported by strict testing, inspection, and quality management at every stage. This commitment ensures clients receive solutions that are reliable, safe, and built to meet or exceed industry standards.

Advanced Metallurgy: By leveraging modern materials science, including high-strength alloys and specialized heat treatments, the company develops components that offer superior durability, precision, and corrosion resistance. Advanced metallurgy translates to longer lifespans and improved performance in demanding operational environments.

Strategic Partnership: Collaboration with leading industry partners enables the business to innovate rapidly, share expertise, and deliver comprehensive solutions tailored to client requirements. Strategic partnerships also enhance resource availability and drive growth through shared success.

Confidentiality: Strict protocols and secure processes are in place to protect sensitive technical data, intellectual property, and proprietary client information. Confidentiality is upheld throughout the project lifecycle, maintaining trust and safeguarding business interests in competitive sectors.