Aerospace Components

Precision Engineering for Aviation Excellence

Engineered for Excellence

Built for Flight

In the high-stakes world of aerospace, every component must deliver unfailing reliability. Vaani Industries produces advanced aerospace parts using cutting-edge fabrication and stringent quality assurance, supporting exploration, aviation safety, and technological progress. Our products ensure outstanding durability and flawless performance under the extreme conditions faced in aerospace missions.

Key Components Highlight ━

- Distance Bush

Components Description

We present a detailed breakdown of the system’s parts, outlining their individual functions and purposes.

Distance Bush

A distance bush is a precision-engineered, cylindrical component designed to maintain an exact gap or distance between two assembled parts or surfaces in aerospace structures.

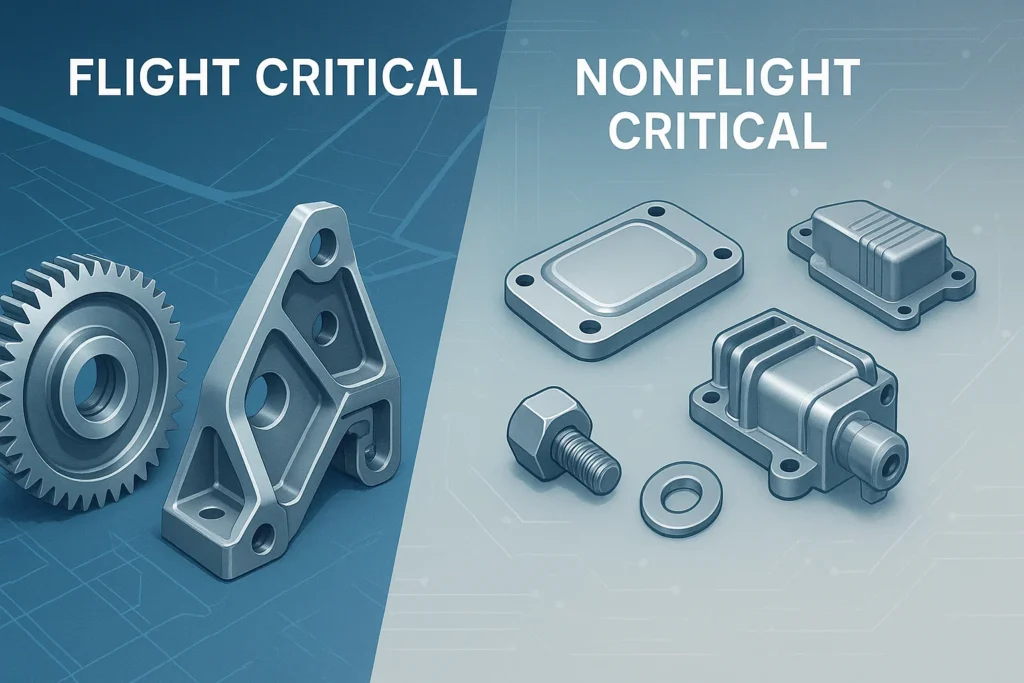

Under Development – Flight & Nonflight Critical Components

We are actively expanding our capabilities to deliver both flight critical and nonflight critical aerospace components. Our engineering team is working on state-of-the-art parts that meet exacting standards for safety, performance, and compliance.

Choosing the right partner for aerospace manufacturing is vital for safety, innovation, and reliability. Vaani Industries delivers advanced aerospace solutions with proven expertise in precision engineering, robust materials, and quality management—driving mission-critical performance in aviation and space technologies.

Zero-Defect Manufacturing Philosophy

Stringent Quality Assurance in Flight-Critical and Non-Flight-Critical Components

Use of Aerospace-Grade Alloys and Composites

Maximum Strength-To-Weight Ratios

Joint R&D for Advanced Aerospace Solutions

Scalable Production for Prototypes and Series Manufacturing

Certified Quality Systems (ISO, AS9100)

Complete Batch Traceability and Controlled Documentation

Aerospace Precision Engineering: This practice involves designing and manufacturing aircraft and spacecraft components to extremely tight tolerances using advanced machining, CAD modeling, and in-process inspection. The goal is to ensure each part maintains precise geometry, surface finish, and fit—critical for flight safety and long-term reliability in challenging environments.

Advanced Materials & Metallurgy: Aerospace manufacturers employ high-performance metals such as titanium alloys, nickel-based superalloys, and specialized composites, often developed with cutting-edge heat treatment and process controls. These materials provide superior strength, fatigue resistance, and lightweight properties, allowing aircraft to perform under extreme temperature and pressure conditions.

Strategic Partnerships with Leading Aviation Firms: Working closely with top aviation organizations and OEMs allows for collaborative innovation, knowledge sharing, and alignment with fast-evolving industry standards. These partnerships enable access to new technologies, continual improvement of parts and processes, and accelerated delivery of mission-critical solutions.

Safety, Reliability, and Compliance: Aerospace production is governed by strict certifications (like AS9100), rigorous testing, and thorough quality management at all stages, ensuring products consistently meet global safety and reliability benchmarks. Compliance processes—including material traceability, environmental controls, and regular supplier audits—guarantee flight-critical systems perform without compromise.