What is a Brake Gear Arrangement for WAG-9/WAP-7 locomotive?

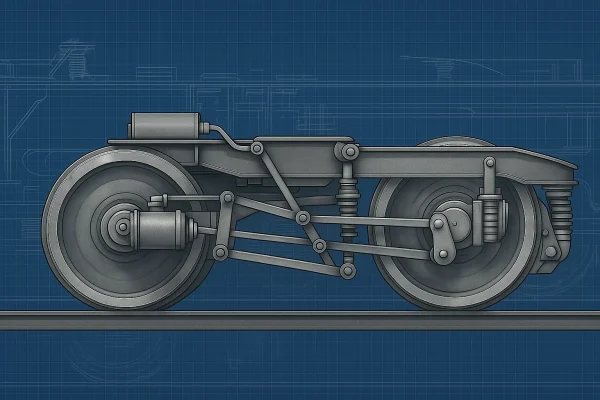

The Brake Gear Arrangement in WAG-9 and WAP-7 locomotives is a sophisticated integrated system that combines pneumatic, dynamic, and mechanical braking methods to ensure effective control and safety of high-speed and heavy freight trains. It is designed for reliable, balanced braking effort supporting diverse operational scenarios such as emergency stops, parking, and speed regulation.

Key Features of Centering Discs

Regenerative Braking System:

Converts kinetic energy into electrical energy using the locomotive’s traction motors, enhancing energy efficiency and reducing wear on mechanical brakes.

Pneumatic Automatic Train Brake

Provides primary braking force controlled via compressed air, ensuring responsive and fail-safe operation.

Direct Loco Brake

Allows independent control of brakes on the locomotive itself, improving braking precision and safety.

Parking Brake Mechanism

A mechanical or pneumatic system that holds the locomotive stationary when parked.

Anti-Spin Feature

Prevents wheel slip during acceleration or braking, maintaining traction and minimizing track damage.

Balanced Braking: Coordinates between pneumatic and regenerative systems to distribute braking effort evenly across all driving axles.

Emergency Braking: Enables rapid brake application in critical situations to stop the train safely.

Speed Regulation: Integrates with speed sensors and control units to modulate braking as per speed requirements.

Energy Efficiency: Uses regenerative braking to recover energy, improving overall locomotive efficiency.

Brake Force Monitoring: Continuously monitors brake cylinder pressure and brake effectiveness to ensure safety.

Fail-Safe Operation: Automatically switches to pneumatic braking in case of regenerative brake failure.

Driver Control Interface: Provides intuitive controls for the driver to manage various brake modes and monitor system status.