Automative Components

Engineered for Excellence, Built for Performance

Engineered for Excellence

Built for Road Performance

In the dynamic world of automotive engineering, every component is designed with precision, durability, and safety. Vaani Industries specializes in advanced automotive parts using high-strength materials and certified quality systems, supporting innovation and reliability for motorcycles, commercial vehicles, and specialty transport.

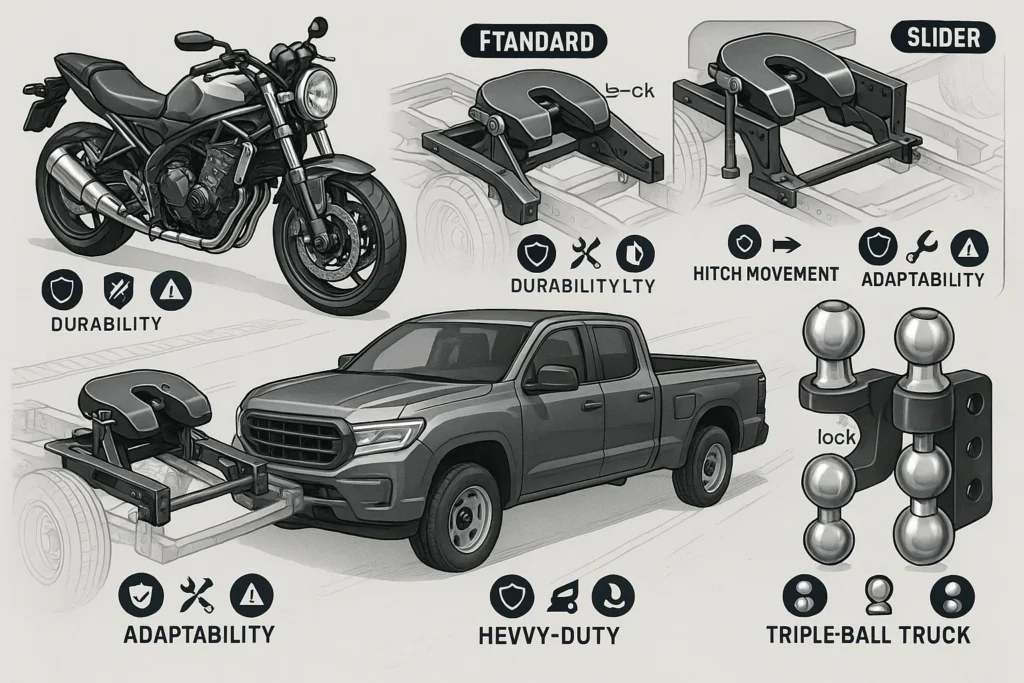

Key Components Highlight ━

- Motor Cycle Assembly

- 5th Wheel Hitch Standard

- 5th Wheel Hitch Slider

- Truck Hook Double Ball

- Truck Hook Triple Ball

Components Description

We present a detailed breakdown of the system’s parts, outlining their individual functions and purposes.

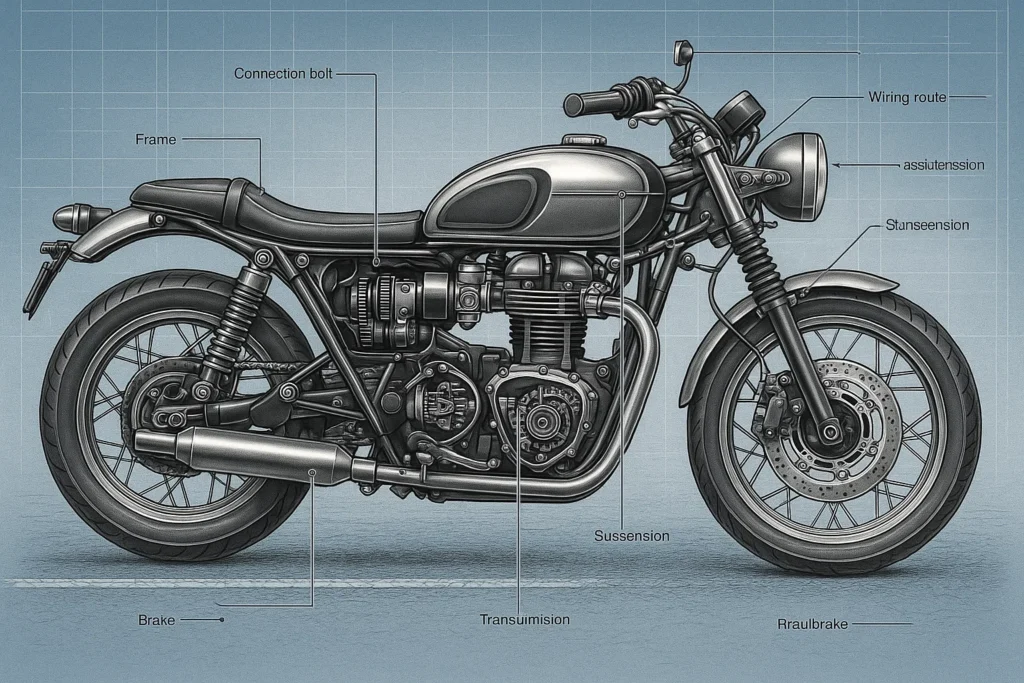

Motor Cycle Assembly

Motor Cycle Assembly refers to the complete collection and integration of all mechanical, electrical, and structural components required to create a functioning motorcycle. This includes the frame, suspension, engine, transmission, wheels, steering, brakes, seat, and electrical wiring harness.

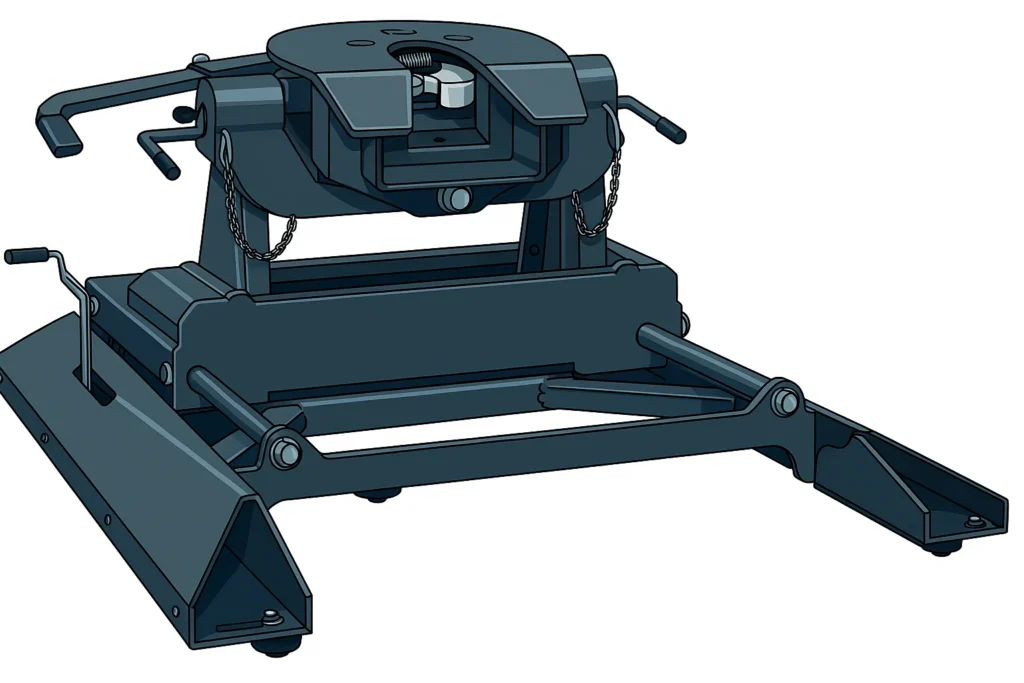

5th Wheel Hitch Standard

The 5th Wheel Hitch Standard, commonly known as a Fifth Wheel Hitch, is a heavy-duty towing component widely used to connect trucks or trailers, especially in automotive and logistics industries.

5th Wheel Hitch Slider

The 5th Wheel Hitch Slider is an advanced variant of the standard fifth wheel hitch, designed for trucks and trailers that require added maneuverability in tight spaces or for short-bed vehicles.

Truck Hook Double Ball

The Truck Hook Double Ball is a specialized towing accessory designed for heavy-duty trucks, enabling secure and flexible attachment of multiple types of trailers or towing equipment.

Truck Hook Triple Ball

The Truck Hook Triple Ball is a versatile towing accessory designed for trucks, enabling rapid adaptation to a wide range of trailer coupler sizes and types.

Choosing a trusted partner for automotive manufacturing is essential for safety, performance, and innovation. Vaani Industries delivers precision automotive components with cutting-edge fabrication, robust materials, and certified quality management—empowering vehicle reliability and efficiency on the road.

Zero-defect manufacturing and rigorous inspections at every stage.

Built to withstand challenging road and towing environments.

Use of automotive-grade alloys and innovative design for strength and adaptability.

Components engineered for motorcycles, trucks, trailers, and specialty vehicles.

Scalable manufacturing for assemblies and custom components.

Technical support for OEMs, aftermarket, and fleet operators.

Stage-wise testing and certifications for all products.

Reliable connection systems for safe transport and towing.

Proven Automotive Engineering Expertise: The organization brings extensive experience and technical knowledge in designing and manufacturing automotive components. Its engineering teams leverage industry best practices to deliver precision-engineered solutions that meet complex vehicle performance and durability requirements.

Advanced Metallurgy & Quality Assurance: Utilizing cutting-edge metallurgical techniques and strict quality management systems like IATF 16949, the company ensures materials and manufacturing processes produce highly durable, reliable components. This commitment facilitates defect-free production and long-lasting automotive part performance.

Versatile Solutions for Diverse Application Needs: The company adapts its manufacturing capabilities to serve varied automotive sectors including motorcycles, commercial vehicles, and specialty transport. This flexibility ensures tailored product designs that meet different operational demands and industry specifications with efficient scalability.

Safety, Reliability, and On-Time Delivery: A rigorous focus on functional safety standards and effective process controls guarantees safe and dependable outputs, backed by a track record of meeting delivery schedules. This reliability supports customer trust and vehicle operational readiness in competitive markets.